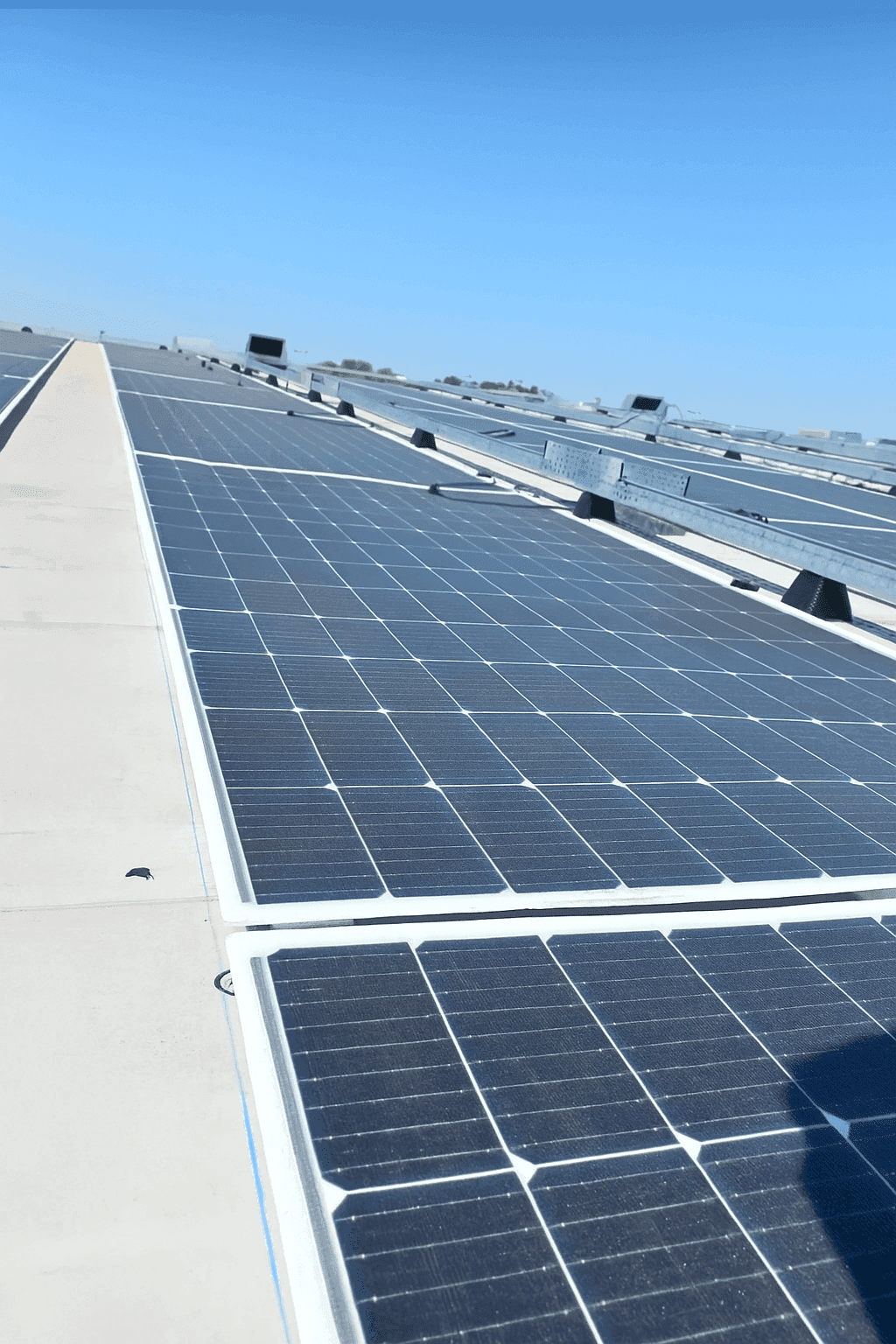

Monocrystalline Panels: High Efficiency and Elegant Design

Monocrystalline photovoltaic panels are among the most commonly used types. Made from a single silicon crystal, they offer higher efficiency (17–24%) compared to polycrystalline panels. They have a homogeneous appearance and a dark to black color. The individual cells are characterized by rounded corners.

Monocrystalline panels are ideal for applications with limited space, where high performance is required – typically on the roofs of homes, commercial buildings, or industrial halls.

Polycrystalline Panels: Cost-Effective Solution

Polycrystalline silicon panels are manufactured using simpler technology, resulting in a lower initial cost.

The surface is typically blue to light blue, and their efficiency is generally lower than that of monocrystalline panels. While polycrystalline panels are gradually being phased out, they are still used in some cases.

Bifacial Panels: Energy from Both Sides

Bifacial panels can utilize not only direct sunlight hitting the front (top) side, but also reflected or diffused light from the rear (bottom) side. Both the front and rear surfaces of the panels are made of glass, allowing both sides to actively generate electricity.

This type is ideal for large solar farms, applications in mountainous and snowy areas (as snow reflects light very efficiently), and agrivoltaics. At Greenbuddies, we commonly install them on large industrial roofs with a glossy surface.

Lightweight Panels: Solution for Roofs with Limited Load Capacity

Lightweight photovoltaic panels are used when the roof structure has limited load-bearing capacity.

The front side is made of plastic, while the back is made of polymer or aluminum, framed either with a thin aluminum frame or completely frameless. These panels are flexible and can be slightly bent.