Selecting land for PV plants

Choosing the right location is essential. Factors such as orientation, accessibility, zoning, and environmental limits are evaluated. Modern technologies such as drones help to refine the focus and facilitate decision-making at this stage of the project.

Studies for the construction of a PV power plant

- Surveying the site with a drone

Drones provide accurate and up-to-date data on the terrain or roofs where the photovoltaic power plant is to be built. This allows potential technical obstacles to be quickly identified but also serves to map the current state of the land or roof.

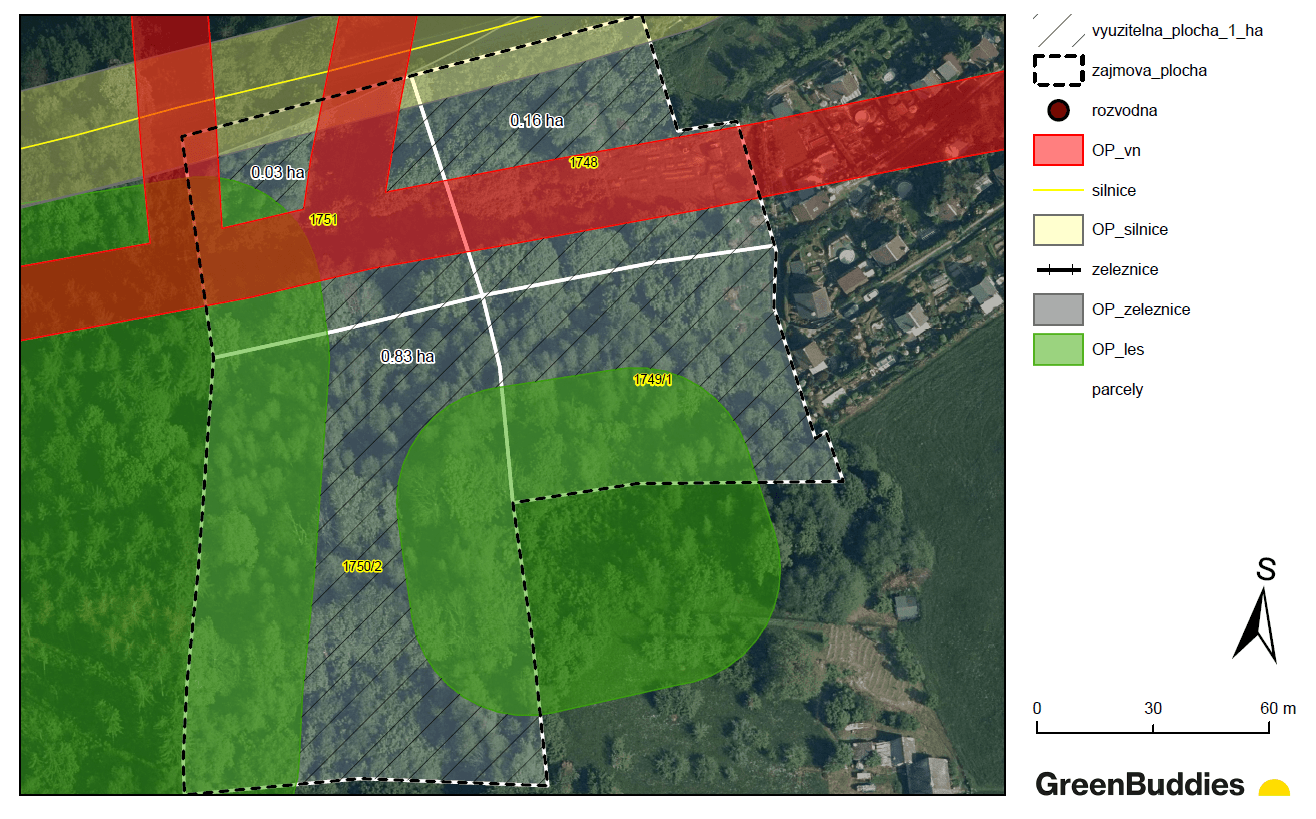

- Administrative study

An administrative assessment of the land reveals and eliminates project risks, helping to prevent unnecessary investment losses and facilitating effective decision-making when selecting an investment project. An experienced team assesses the location in terms of legislation, nature conservation, and the availability of networks and infrastructure.

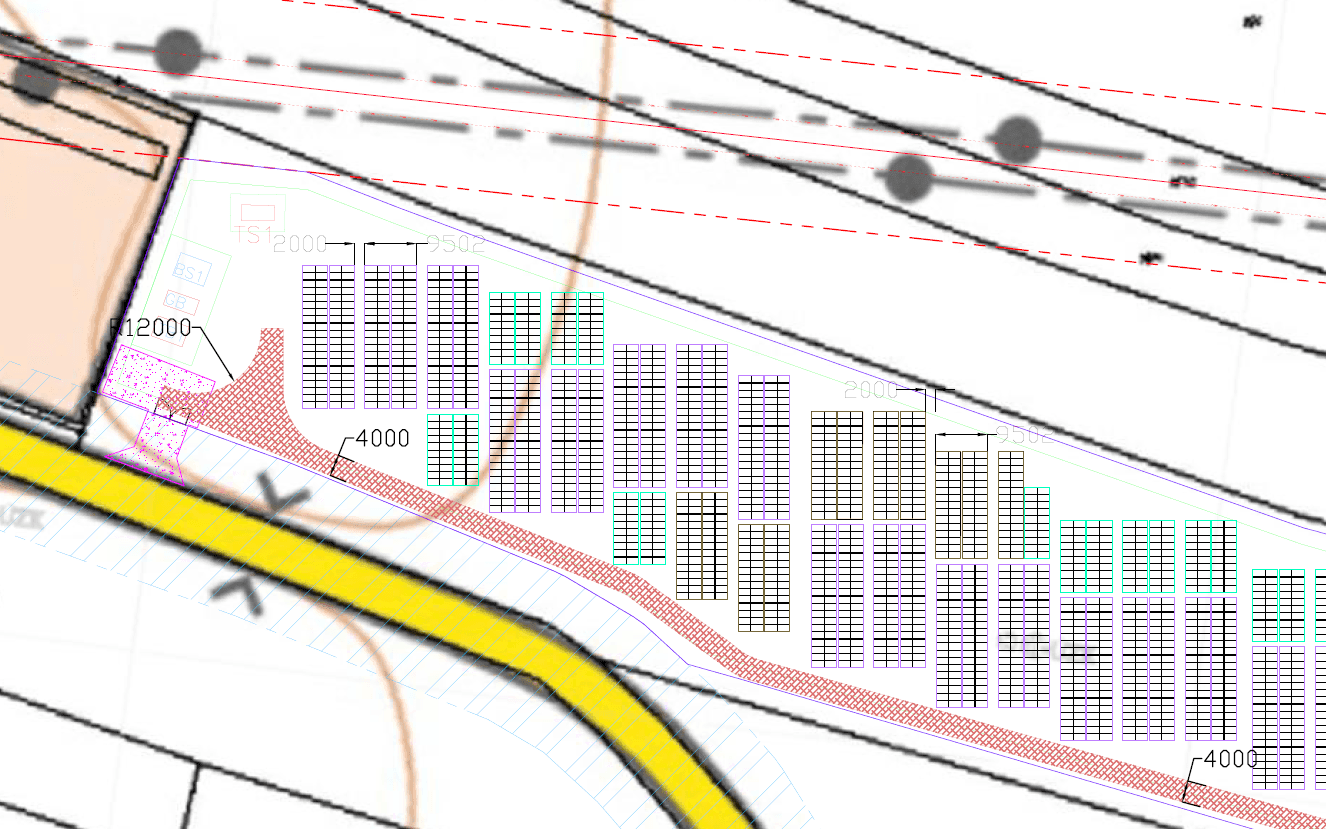

- Technical study

A technical study assesses the possibilities for locating a power plant on land or a roof.

For ground-mounted power plants, the terrain, its condition, the orientation and slope of the land, and possibly its shading are evaluated. Subsequently, a technical solution is created – from a preliminary PV design, an indicative layout of the panels, and the location of access and service roads to a more detailed specification of the solution. This design can also be used to calculate a rough estimate of the installed capacity in MWp and the annual production of the power plant in MWh. Another important aspect is the design of the connection to the distribution network.

For rooftop PV power plants, the load-bearing capacity of the roof and fire safety are also assessed.

- Economic study

The economic study compares the costs and revenues of the project and assesses potential economic risks. It addresses investment costs (land, technology, installation, and related administrative costs) and operating costs (service, maintenance, monitoring, and insurance costs), while revenues include, in particular, revenues from the sale of electricity and, where applicable, savings on own consumption. It also analyses the effects of the market, legislation, and financial stability. Working with scenarios and sensitivity analysis is standard practice.

Documentation and building permit (1–3 years)

Includes complete land development, including zoning plan changes, EIA, IGP, and obtaining a building permit.

Implementation documentation (2–3 months)

Preparation of final project documentation for construction, budget, and bill of materials.

Purchase of PV components (2–3 months)

The purchase phase involves the selection, ordering, and delivery of key components of the solar power plant—panels, structures, inverters, cabling, substations, and switchboards. Emphasis is placed on quality, price, and timely delivery.

Construction of the PV plant (2–3 months)

The actual construction of the solar power plant is a relatively short period of weeks to several months, involving the assembly of structures, panels, electrical installations, and security elements. At the end, a physically completed PV plant is created. This phase mainly includes setting up the construction site, preparing the ground (for ground-mounted power plants, for example, levelling the terrain), and the subsequent mechanical installation of all components. This is followed by excavation for cabling, laying and distribution of cables, and complete electrical installation. The construction process is supervised by one or more site managers, who report to a project manager who coordinates the construction and communication with the customer.

Commissioning of the PV plant (4–12 months)

- Final inspection

After construction, the installation undergoes a final inspection by the Authority Having Jurisdiction (AHJ)—typically the local building department and electrical inspector—and, where applicable, the fire marshal or other local authorities. Any punch-list items are resolved, and the contractor submits as-built drawings, O&M manuals, and safety documentation to close out the build phase.

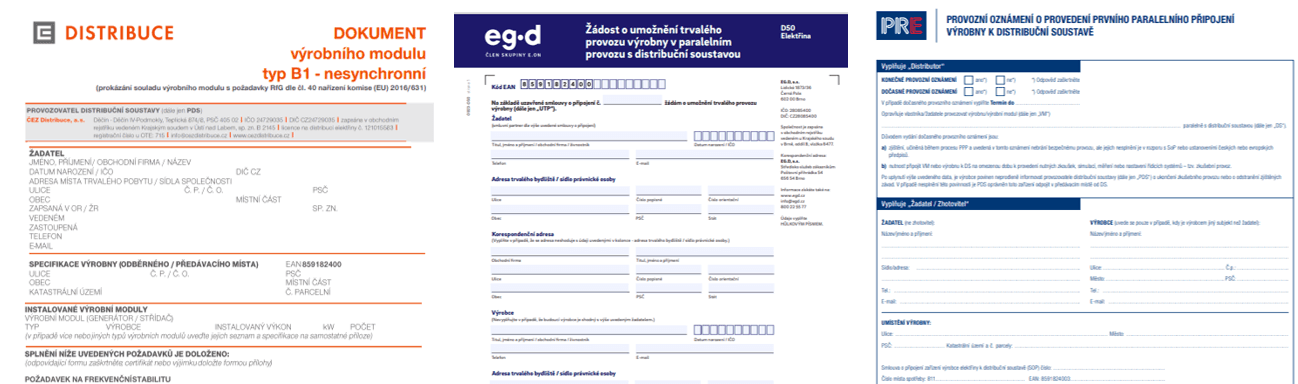

- Licenses

All building/electrical permits are closed with the AHJ, and the interconnection agreement with the utility/grid operator is executed, including revenue-grade metering and telemetry. Where required for larger plants, a generation license/registration is obtained (often with evidence of technical capability and financials). If the project will participate in wholesale markets, it completes registration with the relevant market operator (ISO/RTO) or, alternatively, finalizes a retail supply contract or PPA with the offtaker.

- Commissioning

Commissioning proceeds through pre-functional checks (insulation resistance, polarity, grounding, IV-curve sampling, tracker verification, SCADA connectivity, inverter settings) and grid-code compliance tests (protection/relay, anti-islanding, ride-through, reactive power/Volt-VAR), often with utility witness testing. Performance verification and Site Acceptance Tests (SAT) are documented. Once interconnection and safety criteria are met, the utility issues Permission to Operate (PTO), authorizing continuous operation. The project declares its Commercial Operation Date (COD), completes any remaining registrations, and begins commercial settlement per the PPA or supply contract, with ongoing monitoring, reporting, and preventive maintenance.

Aggregation, Storage, Monetization

Modern PV plants are no longer just about generation—they’re about flexibility. Energy can be stored, used to cover on-site consumption, or sold into the market when pricing is favorable. Battery Energy Storage Systems (BESS) and intelligent energy management/dispatch play a central role in unlocking these value streams.

Maintenance

The final key to long-term PV efficiency is regular PV maintenance: cleaning panels, cutting vegetation, and checking the system. Our Greenbuddies teams provide maintenance for both ground-mounted and rooftop installations.